Automatic Box Processing Line

- Product Overview

- Product features

- Technical Parameters

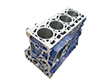

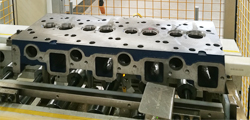

| The project is composed of dozens of horizontal machining centers, which cooperate with the automatic loading and unloading of truss manipulator. The machine tool works 300 days a year and is produced in three shifts, 21.3 hours a day, with an annual output of 200000 pieces. The beat of the production line is ≤ 96 seconds / piece (including all auxiliary time such as loading and unloading time of manipulator 25 seconds, probe replacement time and detection time). The part processing content CMK ≥ 1.67 | |

| Engine cylinder > more | ||

|  | |

01、Truss robot with superior performance Compact structure design , no motor on Mechanical joint ,6 axis joint movement .all axis with RV speed gear box , high performance FANUC servo system , reposition accuracy :±0.07. | 02、 Compound claw Pneumatic control compound gripper, which can turn 90 degrees and has buffer function, is suitable for workpiece loading and unloading of different machine tools. | |

|  | |

03、Circulating material channel Multiple workpieces can be placed for circulation, only one worker is needed for manual loading and unloading, and there is a material retaining cylinder and detection device. | 04、Sampling inspection slide The turnover device is generally located between two lathes and is pneumatically controlled for 180 degree rotation of the workpiece for U-turn turning. | |