- Brief

- Typical

Brief

Pattern is an integrated part of the manufacture industry. Comprised of injection pattern,pressing pattern,die-casting pattern and forging pattern,the modern patterns become more and more complicated and the products need to be updated at a quicker speed. More and more CNC equipment might meet the need of this situation.

High speed and accuracy are the basic requirement for pattern making. Neway CNC equipment is of reasonable design,high accuracy and high efficiency. VMR machines with hard rail are good for curve process and HM machines for large size pattern making.

Typical Workpiece

-

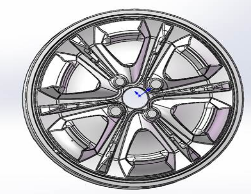

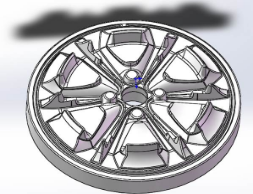

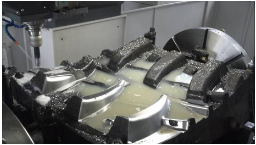

Wheel Hub Pattern

Collapse Shrink

Characteristics:

1. die steel wheel hub patterm, hardness HRC28-32

2.need long tool with heavy duty cutting rigidity

3.rough machining remove allowance, heavy cutting work

Model recommended:

VM903H Vertical milling center

Basic requirement:

1. 8000 spindle

2. coolant around spindle

3. box ways

4. with 1:4 transmission ratio gear box

1.OP10:positioning by profile, rough machine back side

2.OP20:positioning by the pin holes made by OP10, rough machine front face

3.OP30:positioning by the surface made by OP10, rough or fine machine the back side

4.OP40:positioning by the pin holes made by OP10, fine machine front face

-

Tyre Pattern

Collapse Shrink

Characteristics:

large size tyres are difficult to process for heavy cutting work and strict accuracy requirement. need to make in segments. diameter could be 2M-6M

Model recommended:

PM1220H double column milling center

Basic requirement:

1. reliable, efficient and accurate

2.BT50 spindle, fowerful spindle motor

3.professional fixtures

finish all machine jobs with one process on the rotary table

3787158.jpg)

8291241.jpg)

1546764.jpg)

5762251.jpg)