- Brief

- Typical

Brief

Vehicle industry is in market for CNC machines in large quantity to meet the need of updating. It is critical to have efficient, stable and durable machines and mature process control.

For vehicle industry, we recommend composing production lines for highly integrated production by using our efficient,stable and multi functional machines.

Typical Workpiece

-

Turbocharging Case

Collapse Shrink

Turbocharging Case

Characteristics:

Turbocharging cases are usually multi-face part made of aluminium with thin wall and complicated structure, roughness 0.4, strict bore accuracy requirement.

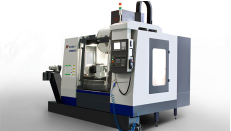

Model Recommend:

Automatic Production Line

NL251H horizontal lathe

VNL502H vertical lathe

VM903H vertical work center

Basic requirement:

1.high reliability and efficiency;

2.coolant through spindle;

3.hydraulic fixture;

4.I/O interface prepare;

5.fixture clean function;

6.tool break test;

7.spindle overload protection;

8.oil mist collector;

9.oil skimmer;

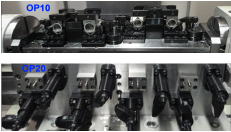

OP10 lathe clamps on OD, turning OD and ID.

OP20 processes OD,the other end and ID.

OP30 positioning by the processed hole and side, processes holes on top and bottom side along with 4th axis rotation

OP40 positioning by the processed hole and side, bores and mills along with spindle rotation

-

Automobile Steering Shaft

Collapse Shrink

Steering Shaft

Characteristics:

Tlong,thin shafts with strict accuracy and runout requirement

Models Recommended:

Automatic Production Line

NL201HG horizontal lathe

VM903SL vertical work center

Basic requirement:

1.hydraulic pressure;

2.high speed cutting;

3.spring power lock;

4.CNC-255 rotary table and hydraulic center tailstock

OP10:clamps on OD in the middle, positioning by end face, turns end face of lesser end, drills center bore.

OP20:clamps on OD in the middle, positioning by end face, turns end face of bigger end, bevels spline bore.

OP30:power lock clamps in bore, hydro tailstock presses workpiece, turns OD.

OP40:mounts on 4th axis, power lock in bore, tailstock presses workpiece,mills slots and drills holes.

-

Aluminium Automobile Wheel Hub Spokes

Collapse Shrink

Aluminium Automobile Wheel Hub Spokes

Characteristics:

1.to reduce weight, the hubs are made by forgings, milled and cut to prevent deformatiion

2.pattern profiles tolerance±0.02

3.clear vein patterns

Model Recommend:

VM903H vertical work center

Basic requirements:

1.12000 rpm direct connection spindle;

2.circular spindle coolant;

3.ball guideway, rapid traverse 36 meter/minute

4.extended Y axis travel;

5.high speed cut

1.OP10:centered by the center bore and positioned on finished surface, oriented by valve, mill the spoke side surface of the aluminium alloy wheel hub.

-

Truck Retarder Case

Collapse Shrink

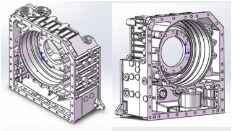

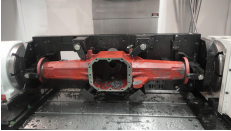

Workpiece:Truck Retarder

Characteristics:

offset center,centrifugal, easy deformation, need more support cylinders.

Working Process ①

Recommended:VNL803H Vertical Lathe

Basic Requirement:

1.hydro fixture; 2.HS cut,powerful spindle motor;

3.coolant through spindle;

4.waterproof;

5.tool measure

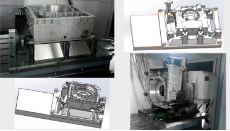

6.woripiece measure

OP10:vertical lathe hydro fixture - rough machine top side. a 32*32 circular tool cuts end face, depth 7mm,a dia.50mm borer cuts diameter by 5mm removing tolarence, a 80mm tool shangk with 25*25 counter borer makes rough hole dia 240, working time 11.56 minutes.

Workpiece:Truck Retarder

Characteristics:

offset center,centrifugal, easy deformation, need more support cylinders.

Working Process ②③④

Recommended:VM1204S Vertical Work Center

Requirement:

1.hydro fixture

2.4th axis rotary table

3.HS cutting, powerful spindle motor

4.coolant through spindle

5.waterproof requirement

6.tool measure

7.workpiece measure

8.extended spindle by 200mm

OP20:vertical milling center fixture, position by φ300 hole that finished by OP10,orient by profile, make holes on top and bottom surfaces, number of tools 15, working time 12.16 minutes. OP30:vertical milling center fixture, based on surface finished by OP20,position by 2-φ10, make all holes on top surface and stots as well as all bottom holes. Working time: 12.04 minutes. OP40:vertical milling center fixture, based on surface finished by OP20,position by 2-φ10,machine 4 surfaces and all holes around, time consumption 12.23 minutes.

Workpiece:Truck retarder

Characteristics:

holes φ300 and φ299.5 φ301 φ120φ240 tolerance is H7

D300 hole perpendiculars requirement 0.03mm

coaxiality between 3D300 hole and D240 hole are required to be 0.03mm, made by 180°rotation of the rotary table.

thin wall work piece that need to be made step by step in order to avoid deformation by caused by fixturing or processing.

Working Process ⑤

Recommended:HM63TS Horizontal Work Center

Requirement:

1.hydro fixture

2.4th axis rotary table

3.HS cutting, powerful spindle motor

4.coolant through spindle

5.waterproof requirement

6.tool measure

7.workpiece measure

OP50:Vertical milling center fixture,based on the surface that OP20 processed and positioned by the 2-φ10 holes, process other 2 surfaces and OP40 left holes; fine machines surface, fine bores φ300,φ299.5 φ301 φ120 and φ240. number of tools 40, working timme 12.16 minutes.

-

Front Axle

Collapse Shrink

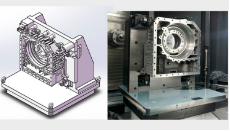

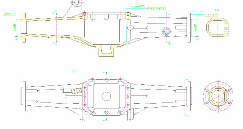

Characteristics:

Front axis has many surfaces to process. difficult to turnover, heavy cutting work, high roughness requirement, perpendicularity 0.025, positioning 0.025. Indexing table rotates 3 times and finishes all job with 1 mount.

Model recommended:

VM1506H Vertical Milling Center

Basic requirement:

1.high reliability and efficience;

2.rational layout, good rigidity;

3.easy chip and water removal;

4.BT50 spindle, powerful spindle motor.

4th axis rotates 3 times and finish all job with one process.

-

Vehicle Knuckle

Collapse Shrink

Characteristics:

large cutting amount, long hole span, strict coaxial,finishing requirement, rigidity and chip removal function.

model recommended:

VM1204H/VM1304H vertical work center

requirement:

1.special manual or hydro fixture

2.rotary table

3.HS cutting,powerful spindle motor

4.coolant through spindle

5.strict waterproof requirement

OP10 fixation: position by bottom surface, pin,angular

positioning,press 2 points on top.

OP20 fixation: position by bottom surface, pin,angular

positioning,press 2 points on top.

-

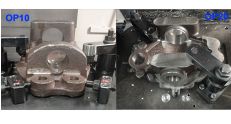

Carburetor

Collapse Shrink

Characteristics:

TCarburetors are multi-side valve type parts, aluminium thin wall, complicated shape, accuracy requirement 0.4,strict bore accuracy.

Model Recommend:

VM903S Vertical machine center

Basic requirement:

1. highly reliable and efficient

2. coolant through spinddle 3. hydro fixture

OP10 4th axis and tailstock, process 4 sides with one mount, ¢26 bore tolerance reaches 0.01,roughness 0.1

OP20 2 location pins, hold part with cylinder and process the other side.

-

Vehicle steering knuckle

Collapse Shrink

Characteristics:

quantity cut, long hole span, strict co-axial,finish, rigidity and bore chip removal requirement

Model Recommend:

VM1204H/VM1304H vertical milling center

basic requirement:

1.special manual or hydro fixture

2.4th axis rotary table

3.high speed cut,powerful spindle motor

4.coolant through spindle

5.strict waterproof requirement

OP10 positioning by bottom side and pins, fixture holds part by two positions

OP20 positioning by bottom side and pins, fixture holds part by two positions

-

Aluminium wheel hub

Collapse Shrink

Characteristics:

large diameter, thin wall, strict requirement for roughness, machine rigidity and cover seal.

Model Recommend:

NL633HW vertical CNC lathe

basic requiremtn:

1.special manual or hydro fixture

2.4th axis rotary table

3.high speed cut,powerful spindle motor

4.coolant through spindle

5.strict waterproof requirement

VM1103H vertical milling center

Process

OP10 positioning by bottom side and pins, fixture holds part by two positions

OP20 positioning by bottom side and pins, fixture holds part by two positions

-

Connecting Rod

Collapse Shrink

Characteristics:

1. Strict accuracy requirement, hole tolerance grade 6, roundness and cylindricity 0.008,hole parallel 0.01

2. 工件材料为C70S6 or ASTM 5140,hard and difficult to process

Model recommended:

VM1103S Vertical Milling Center

Basic requirement:

1. Hydraulic fixture; accurate coolant through BT50 spindle

5212314.jpg)