Efficient Processing Solution of Spinneret 0.2mm Micro-hole from Neway CNC Equipment

2020-05-17

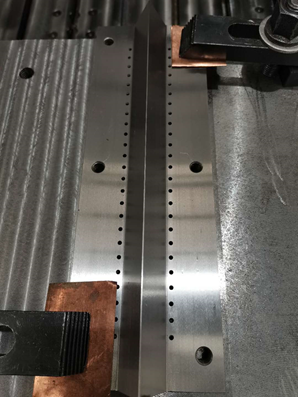

The core component of the melt spraying cloth production equipment is the spinneret head (spinneret), which has many spinneret holes for the melt to pass through. The spinneret holes are micro-holes with a size of about 0.2 mm, which is difficult to process.

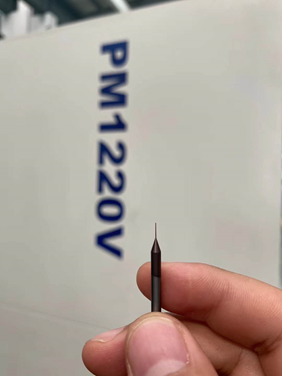

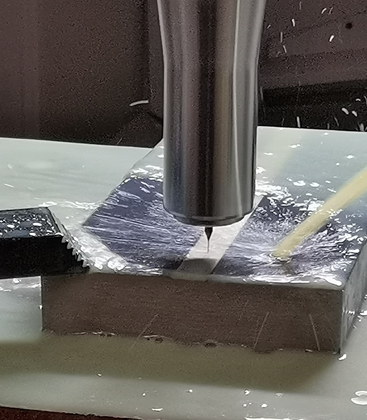

Recently, Neway CNC Equipment has organized technical teams and cooperated with our customers to carry out the technical research on 0.2mm plate hole processing of meltblown cloth. With the high-speed and high-precision gantry machining center and the experienced technical team, we have successfully completed the high-speed processing of 0.2mm micro hole: the drilling depth is 3.65mm, and the processing time of single hole is 54s. Fully meet the requirements of micro-hole precision.

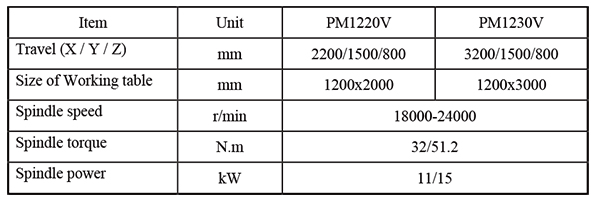

PM12V series high speed and high precision gantry machining center produced by neway CNC equipment is adopted for the micro-hole machining.Thisequipment is mainly used in the cutting industry of high-precision molds and high-precision metal parts. The main features and parameters are as follows:

1. The maximum speed of the motorized spindle is 24000rpm, with high machining efficiency and good surface quality;

2. The spindle adopts an independent cooling system, which greatly reduces the thermal deformation and improves the machining accuracy;

3. With the optimized design of FEA, the dynamic response speed is excellent, ensuring high quality processing;

4. Equipped with oil and gas lubrication system, ensuring high machining stability and longer service life.

Main technical parameters of high speed and high precision gantry machining center -PM12V series:

Vehicle

Vehicle